Challenge to Optical Pickup Optical System Tuning Machine

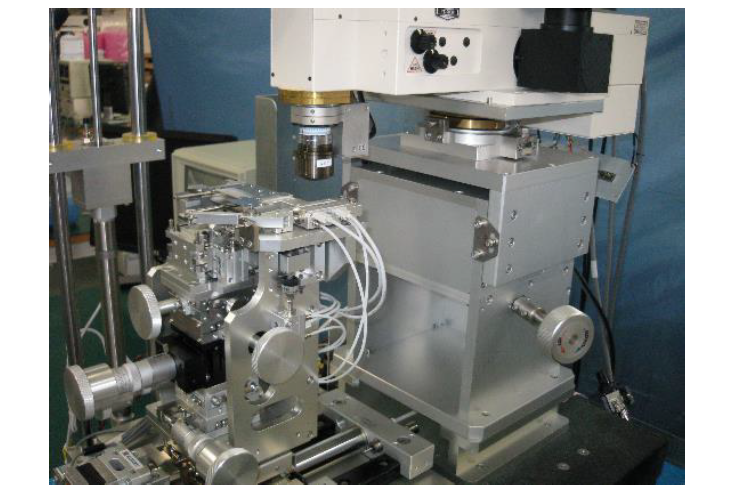

The optical pickup optical adjustment machine introduced here is a device for adjusting and evaluating optical pickups (OPUs) built into optical disc drives.

Optical discs started with CDs, which became popular in the 1980s, and in the 1990s, DVDs spread throughout the world, taking advantage of their random accessibility, which tape media does not offer.

Japanese manufacturers, especially electrical, electronic, and chemical manufacturers, played a leading role in this diffusion process, and Japanese manufacturers were the sole producers of OPUs, which are signal read/write devices mounted on optical disk drives.

In the 1980s, the main method for adjusting and evaluating OPUs on the production line was to use equipment that measured electrical characteristics and made assembly adjustments (electrical characteristics adjustment equipment).

However, the market has been calling for improvements to the electrical adjustment equipment due to problems such as long adjustment time and difficulty in tracking down the cause of defects.

To solve this problem, we have developed a device (optical adjustment device/optical pickup optical adjustment machine) that uses our optical technology to measure the “optical characteristics” of the OPU and perform assembly and adjustment.

The main goal of the development was to achieve a performance (high-speed adjustment) that significantly exceeds the performance of the electrical characteristics adjustment device, and to achieve this, it was necessary to study development using a completely different method than the conventional method.

In electrical characteristics adjustment, OPU adjustment is performed using Jitter, an indicator of signal quality.

However, the best score in Jitter is not a perfect score of 100 points, but the best score varies from 70 to 80 points for each OPU to be adjusted.

In other words, the process of first finding the best score for each OPU and setting the target is necessary, which results in a loss of time.

On the other hand, optical adjustment measures and adjusts the shape of the beam spot emitted from the OPU. Specifically, the adjustment is made to balance the beam spot vertically and horizontally, which means that there are 100 best points.

In other words, since the target and the direction of adjustment are clear, it is possible in principle to eliminate the time loss mentioned above.

However, there is one more problem that must be cleared when it comes to “high-speed” adjustment. It is to find a beam spot as small as 1um at high speed from an out-of-focus and out-of-position state. We were able to solve this problem by using optical sensor technology that simultaneously arranges several functional optical systems within the same housing.

Specifically, the optical system that performs focusing servo and positioning servo can be efficiently coexistent with the measurement optical system to achieve high-speed focusing and positioning servo.

This technology realizes high-speed focusing and positioning servo by efficiently coexisting the optical system that performs the focusing servo and the optical system that performs the positioning servo with the measurement optical system. As a result, we were able to complete OPU adjustment in less than half the time required by the electro-specific adjustment system.

Next, we made various proposals to OPU manufacturers. First, we proposed to the OPU manufacturer a device with an optical characteristics measurement function added to the adjusting machine.

Optical characteristics are expressed as aberrations, or distortions of light that occur as it passes through optical components, and measuring the aberrations that an OPU has makes it possible to identify the cause of these aberrations. We began offering this equipment, which has led to quality improvements for OPU manufacturers.

In addition, by adding the function to measure the aberration of the OPU optical system in the previous stage, the actual amount of aberration that is occurring has become known. Analysis revealed that there are aberrations that can be suggested by adjusting the light-emitting part of the OPU, so we proposed a new device to adjust the light-emitting part of the OPU.

By adjusting the positional relationship between the LD and the lens that collimates the LD light, it is possible to suppress aberrations in the entire OPU.

Although the distance between the LD and the lens has conventionally been adjusted, there are five other axes of adjustment (two tilt axes, two position axes, and rotation).

We developed a device capable of 6-axis adjustment by adding the spacing to these 5 axes, and proposed it to the OPU manufacturer.

This is another example of our technology for developing optical sensors with multiple functions. The OPU manufacturer that introduced this device evaluated that it led to an improvement in the straightness ratio.

In this way, we have contributed to the improvement of OPU production efficiency and straight-through rate by making various actual proposals to OPU manufacturers.

Nowadays, optical characteristic adjustments and evaluations are commonly performed in the OPU production line for Blu-ray, the highest level of optical disc technology.

Our repeated development, proposal, prototyping, and mass production in a short period of time has been our corporate strength.

The technology to develop optical systems with multiple functions inside a single housing is still utilized in inspection devices for auto-focus motors and optical anti-shake (OIS) motors for smart phones.