Tilt sensor (autocollimator)

Tilt sensors are the most basic of all the products we handle and are composed of the most basic core technologies.

Usually, our products are developed based on the measurement needs of our customers, but the tilt sensor was developed as an in-house jig for “assembly” of optical systems in our product factories.

The tilt sensor was born in 1995, the year Windows 95 was released.

With the advent of Windows, the world of the Internet began to become known to the general public, but the Internet environment was still generally based on telephone lines, or analog lines.

Since it was not yet possible to exchange large amounts of data over a network, CD-ROMs and CD-Rs were used to handle large amounts of data.

At that time, we mainly manufactured and sold “spot evaluation devices,” which were devices to evaluate “optical pickups” used to read data from CD-ROMs.

This “spot evaluation device” optically measures and analyzes the shape of the spot produced on the CD-ROM disc by the optical pickup installed in the CD-ROM drive, and evaluates the overall performance of the pickup.

When assembling this “spot evaluation device,” it was necessary to adjust the arrangement of prisms, lenses, mechanical parts, etc., in relation to the reference plane.

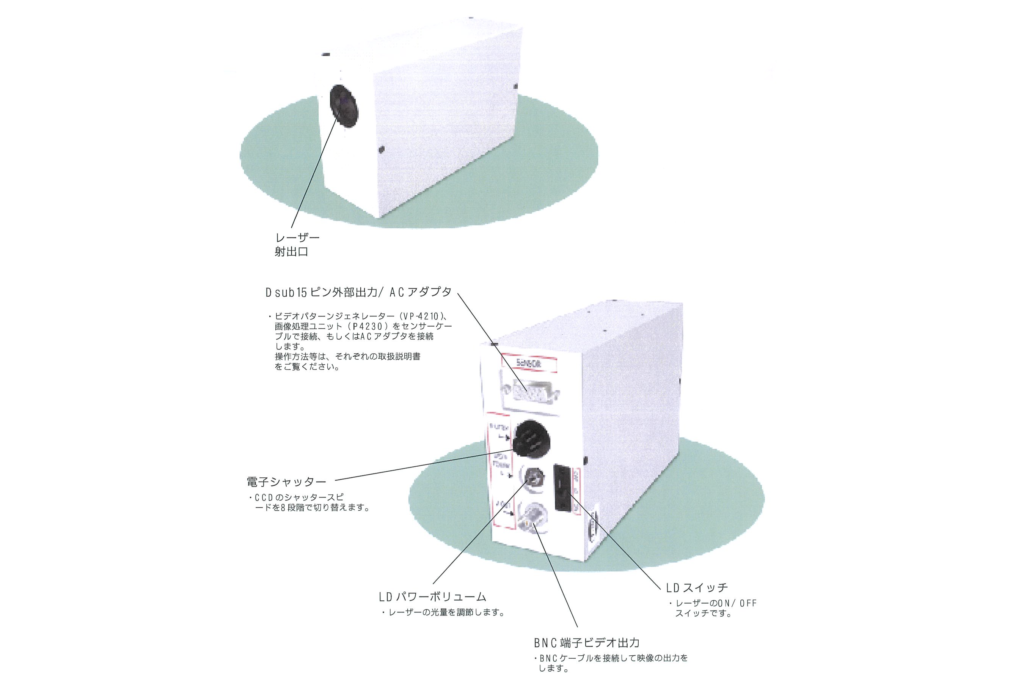

The tilt sensor, a laser-based auto-collimator, was conceived for this adjustment.

The story of how the tilt sensor, which was initially an in-house jig for “assembly,” came to be used by a customer is as follows: One day, when we happened to be at the customer’s plant with the tilt sensor for “start-up” work of the equipment, the customer asked us

Customer “Mr. Katsura Opto, what are you using for that reference check?”

Katsura: “It’s an autocollimator.”

Customer “Such a small thing? How accurate is the measurement?”

Katsura: “It can measure about 1/3000 of a degree.

Customer “I was just looking for something like that. Then can you have 10 units ready in two weeks?”

( “This is it!)

The worker reported the circumstances of the day’s events to the company, and the president immediately began manufacturing the tilt sensor.

A week later, 10 tilt sensors were brought in and officially adopted. At the time, autocollimators were large in size and cylindrical in shape, making it difficult to install them in machinery and equipment.

On the other hand, our tilt sensor was small in size, light in weight, and box-shaped, making it easy to install in machinery.

However, although we marketed the product to other customers, it did not sell immediately.

As mentioned above, autocollimators at the time were recognized as cylindrical and large, and our box-shaped, small autocollimator had a very different shape, so it was not recognized as an object of comparison for other autocollimators.

We gave the autocollimator a new name, “tilt sensor,” to break the existing concept of autocollimator, and continued to introduce it to our customers, which gradually increased its recognition and led to the product we have today, which has been recommended by many customers.